Devices are getting increasingly compact. Every fraction of a millimeter of internal device space is carefully designed by manufacturers to create the smallest and most powerful devices possible. Designs aimed at satisfying consumers’ demand for increased performance in ever smaller devices.

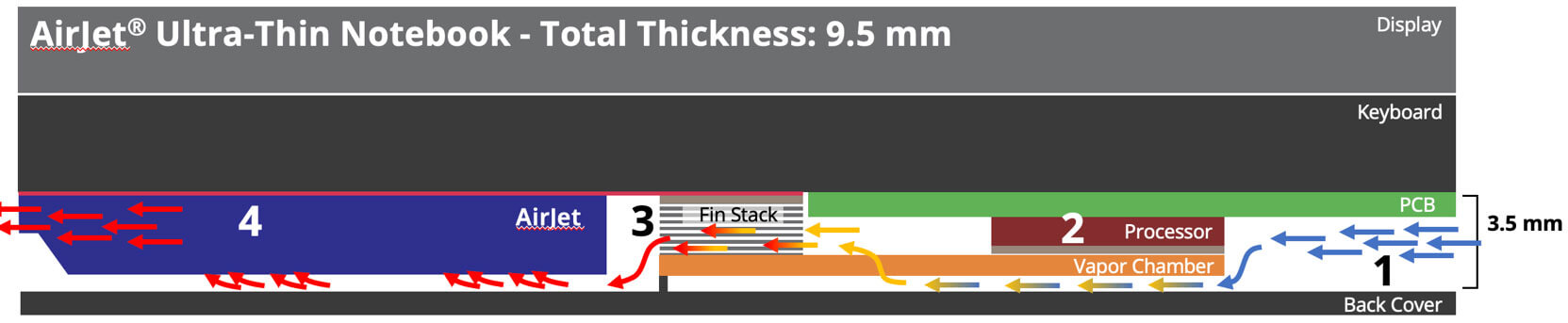

Great examples of this are smart phones and ultra-thin notebooks as thin as 9.5mm, with only 3.5mm of internal space available for placement of critical system components. Performance expectations of these devices however are continually increasing with more powerful CPU’s and GPU’s and growing demands from 5G and even faster future networks. But this increased performance generates heat… a lot of heat.

What is throttling?

Throttling is a protective mechanism aimed at preventing overheating and processor damage. It lowers the performance of your devices well below its real capability - protecting your device by leaving the user frustrated with low performance and slow operation.

To ensure peak sustained performance designers must match up a thermal solution that removes all the heat. If not, processors will slow down (throttle), thus delivering only a fraction of the performance.

In ultra-thin devices, designing a fully capable thermal solution has been a challenge because they are entirely reliant on passive thermal solutions like heat spreaders and vapor chambers. Active cooling using fans to enable higher performance has not been an option. Fans cannot provide active cooling in ultra-thin devices because as fans get thinner, they get less capable, with low air flow and back pressure (or suction power), which is unable to overcome the system resistance inside ultra-thin devices. This effectively reduces the air flow even lower and the amount of additional heat dissipation they remove to near zero.

What is System Resistance?

System resistance is the amount of friction that air encounters as it flows through a confined space such as inside ultra-thin electronic devices. The higher the system resistance, the higher the backpressure (also known as static pressure) is needed to create enough suction force to overcome the resistance and pull air through compact enclosed spaces.

This is why you’ll only find fans in thicker Notebooks with air inlet vents in the back cover; the vents need to be located as near as possible to the fan to reduce system resistance. This inlet vent location, necessitated by the lack of adequate backpressure, is a poor design choice because as soon as the Notebook, intended to be portable and versatile, is placed on your lap (or a cushion as the devices gets uncomfortably warm), the vents are blocked and the fan, with its low back pressure, cannot pull air into the device. This blockage of airflow renders the fans almost useless and increases throttling.

Given the system resistance challenges for ultra-thin devices with only 3.5 mm of internal air gap, actively cooling them to increase performance has been considered impossible… until now.

Airjet’s compact size, only 27.5mm x 41.5mm and, importantly, only 2.8mm in vertical height, is slim enough to fit inside these ultra-thin devices. AirJet’s massive back pressure of 1750 pascals (more than 10 times the suction force of a high-end notebook fan) enables air to be pulled into the device, overcoming the system resistance inherent to ultra-thin devices. Moreover, the inlet vents can be located on the sides and not in the back cover of the Notebook.

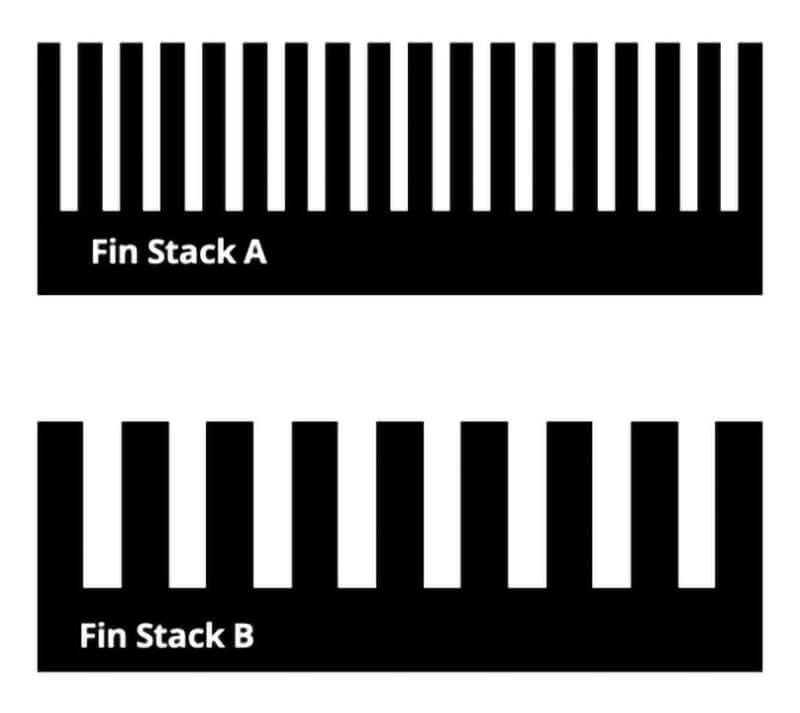

AirJet’s massive back pressure also opens new possibilities for active cooling design in these ultra-thin devices. Until now, the low back pressure or suction force available from fans has limited the ability of manufacturers to maximize surface area on fin stacks for heat removal, as increasing the number of ‘fins’ in a more tightly configured form increases system resistance to unacceptable levels. Consider Fin Stacks A and B below.

Fin Stack A has double the surface area of Fin Stack B, doubling the potential heat removal. So why can’t manufacturers use the more tightly configured fin stack approach in Fin Stack A for traditional active cooling? System Resistance! While Fin Stack A doubles the surface area available for heat transfer, it also significantly increases the system resistance. In fact, decreasing the space between the fins by half, increases the system resistance a massive 700%. So the more tightly fins are packed in the available space, the more backpressure, or suction it takes to pull air through the fin stack. Fin Stack A requires 700% more back pressure to move air though the device and over the surfaces to enable heat to be transferred. Fans simply don’t have the back pressure to overcome this level of system resistance.

This is where AirJet enables a completely new approach to heat removal in these ultra-thin devices. AirJet’s 1750 pascals of backpressure is more than enough to pull air into ultra-thin devices and through unique tightly configured fin stacks enabling active cooling and meaningful heat removal in ultra-thin compact devices for the first time.

The illustration below explains how it all works.

- AirJet’s massive backpressure enables ambient air to be pulled into the most compact device: through a discrete air inlet on the side of the device, and even through dustproof filters.

- Heat is efficiently moved from the heat source (CPU, GPU, modem, or other source) to a fin stack using a 0.7mm thick vapor chamber.

- The Fin Stack, specifically designed for use with AirJet, features a much higher number of tightly configured fins. This innovative fin stack design has never been possible in ultra-thin devices. Traditional fans, with their low suction power, are incapable of overcoming the increased system resistance created by the tightly packed fins. AirJet’s 1750 pascals of back pressure easily pulls air though the design, significantly increasing the exposed surface area for heat transfer.

- The heat saturated air is pulled through the fin stack, by the AirJet and is then expelled completely out of the device through discrete vents on the side of the device.

This innovative approach to active cooling using AirJet, the world’s first solid-state active cooling chip, has opened new opportunities for active cooling in ultra-thin devices delivering up to 100% higher performance in these form factors. To find out more about how AirJet can enable your device to do more, contact Frore Systems.