How AirJet® Helps SWIR Cameras Catch What Others Miss

In high-stakes environments like semiconductor inspection and precision manufacturing, what you can’t see can cost you millions. That’s where SWIR (short-wave infrared) cameras come in — helping machines “see” what the human eye can’t. But even advanced SWIR CMOS sensors have an enemy caused by heat: dark current.

Dark current is a phantom electrical signal that shows up even in complete darkness. And as temperature rises, it gets worse — blurring images, confusing AI models, and sabotaging yield-critical inspection.

So how do you stop something you can’t see?

Understand the Problem:

Not All Dark Current is the Same

SWIR cameras rely on CMOS sensors to convert infrared light into sharp images. But dark current behaves in two very different ways:

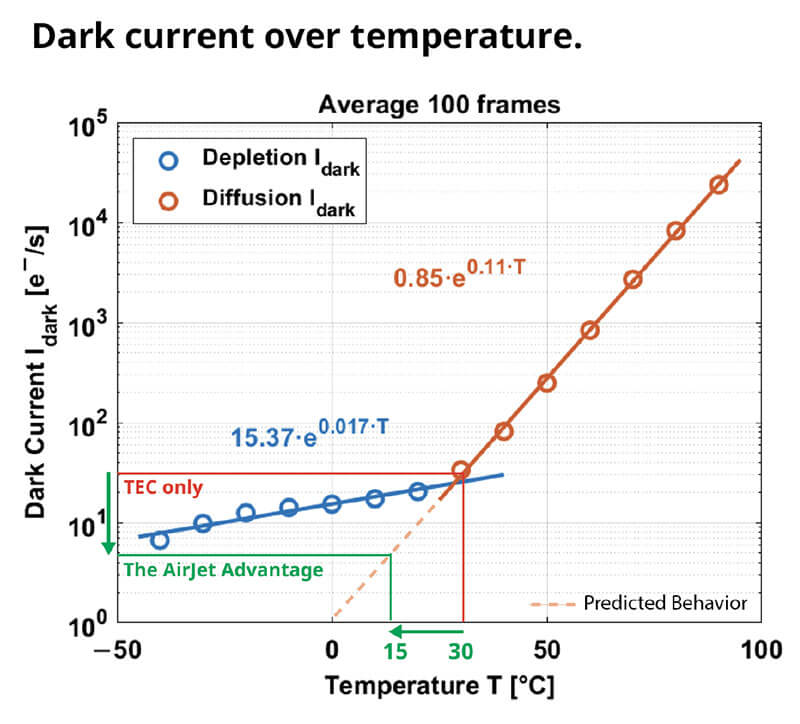

- Depletion Dark Current – Appears at lower temperatures as patchy hot pixels. Easier to fix with software.

- Diffusion Dark Current – Takes over at higher temperatures. Looks like a smooth haze. AI and software struggle to correct it.

Studies show dark current doubles every ~5–10 °C, degrading contrast, signal quality, and data reliability.

Software correction works best on patchy noise (depletion) but struggles with uniform thermal haze (diffusion).

AI struggles with diffusion dark current because it can’t distinguish noise from faint real signals. Lowering thermal noise improves model accuracy and inspection speed.

That’s where AirJet comes in.

Enter AirJet®: Solid-State Active Cooling That Changes the Game

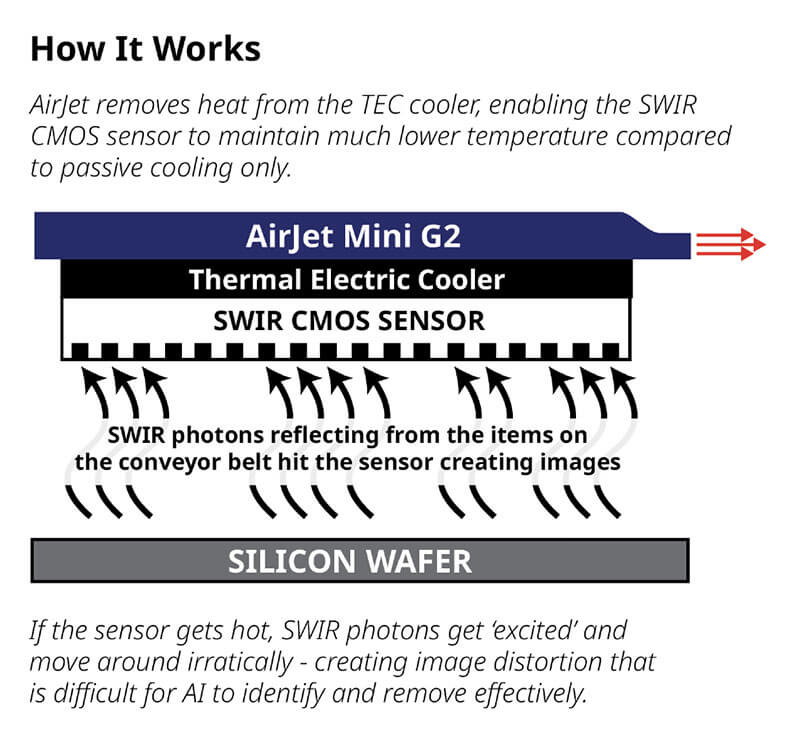

Traditional cooling methods like fans and bulky heat sinks don’t cut it for compact, vibration and dust-sensitive SWIR systems, and Thermal Electric Coolers (TEC) alone are not enough. So Frore built something different.

AirJet Mini G2 works alongside Thermal Electric Coolers (TEC) to deliver an additional 15 °C of cooling — no moving parts, no dust, just silent, stable and accurate solid-state performance and reliability.

With AirJet, you can reduce sensor temperature from 30 °C down to 15 °C — cutting diffusion dark current by 86%.

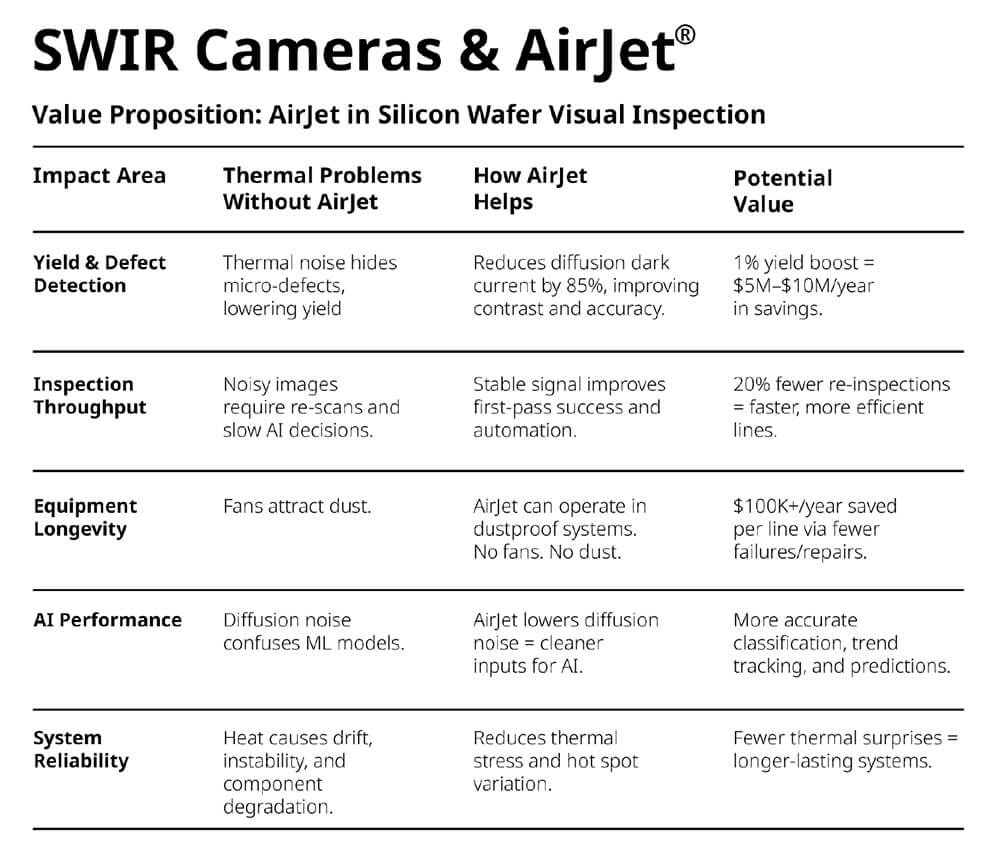

This adds up to real value in precision manufacturing…

Download the white paper with data references here.