Sarah, a manufacturing manager at a large appliance factory, is responsible for overseeing the volume production of a variety of household appliances.

Production had just been ramped up to meet increased demand, when Sarah heard loud voices coming from the server room… and an ominous silence on the factory floor. She went to investigate and found the computer systems overheated, the manufacturing line shut down, and her team arguing about how to reboot the system to get production back online. There was a faint smell of burning in the room which seriously worried Sarah.

Sarah quickly assembled a team of her top engineers to work out what had happened. Assessing the situation didn’t take long. The Mini PCs running the production lines, had embedded fans that had been sucking dust into the system for months. Dust had finally clogged up the fans to the point where they could no longer operate, and the system simply shut down. The team set about replacing the devices so they could restart the line.

As the manager responsible for the site, Sarah knew she needed to find a better solution. She needed a level of performance that just wasn’t available in passively cooled systems without fans. She needed to find a Mini PC that could run the complex programming needed for the line, without getting hot and dusty…

It has long been said that ‘Dust is the worst enemy of anything electrical or mechanical’… and, with the exception of heat of course… that may well be true. Dealing with dust and heat presents a major challenge for environments that need high processing power, in locations which may not always be pristine and dust free. Think about factories, trains, mining operations, retail stores, the list goes on. How do these places, all of which heavily rely on computing performance to operate safely and efficiently, deal with heat and dust.

Until now this type of environment has been limited to bulky, low performance, fanless, passively cooled devices. These passively cooled devices require massive heat sinks to even attempt to remove the heat generated by systems. They end up with the worst possible outcome – low performance, large heavy devices and questionable performance which throttles whenever the systems really need to work.

But why are fans such a problem? These would at least help with performance…. This brings us back to dust and device size. If the system is large enough to contain a small fan, they might have just enough suction power to pull cooler air in from outside the device. The air is then directed through a heat sink, which attempts to remove enough heat from the system to keep things working. Unfortunately, in addition to air, fans inevitably also pull in dust. This dust rapidly accumulates around the fan, eventually causing them to stop working. This problem often makes fans a non-starter, and leaves users struggling to manage heat with passive heat removal approaches that haven’t changed in decades!

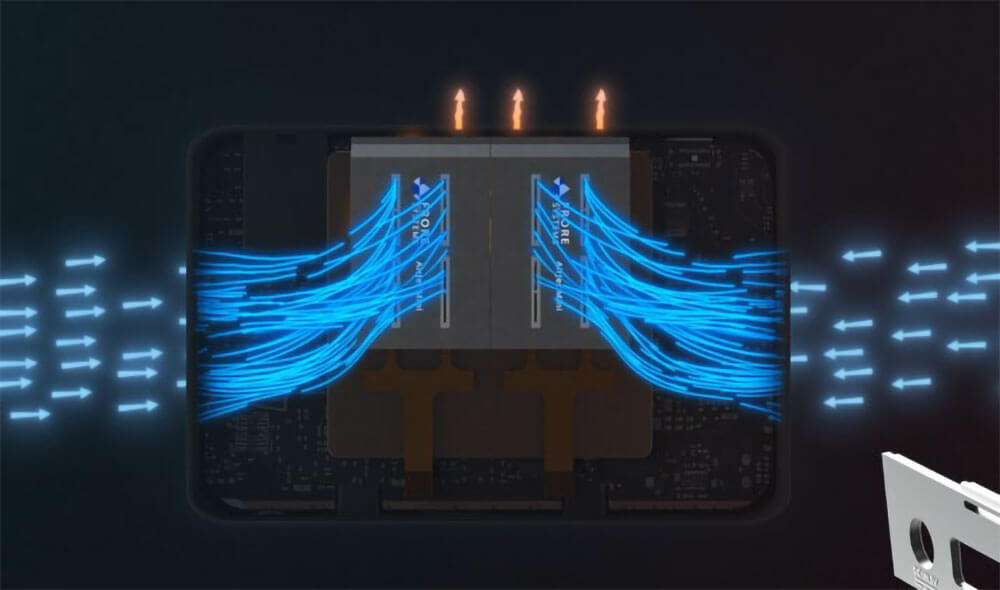

What is needed some kind of ‘super’ fan. A fan that is small enough, but with enough suction force to pull air through a super fine dustproof filter, keeping dust out but letting air in and out of the device. Sadly, no such ‘super’ fan exists. For example, fans small enough to fit in laptop computers create only around 160 pascals of backpressure (the official term for suction force). The level of backpressure needed to pull air into a compact device and then through a dustproof filter to enable dust free cooling is an order of magitude higher.

This is where AirJet, a solid-state active cooling chip, which is revolutionizing heat removal, comes into its own. With an astounding backpressure of 1750 pascals (over 10 times a fan), Airjet can easily pull air into and around compact computing systems, AND critically, through a protective dust filter that makes the AirJet chip impervious to dust.

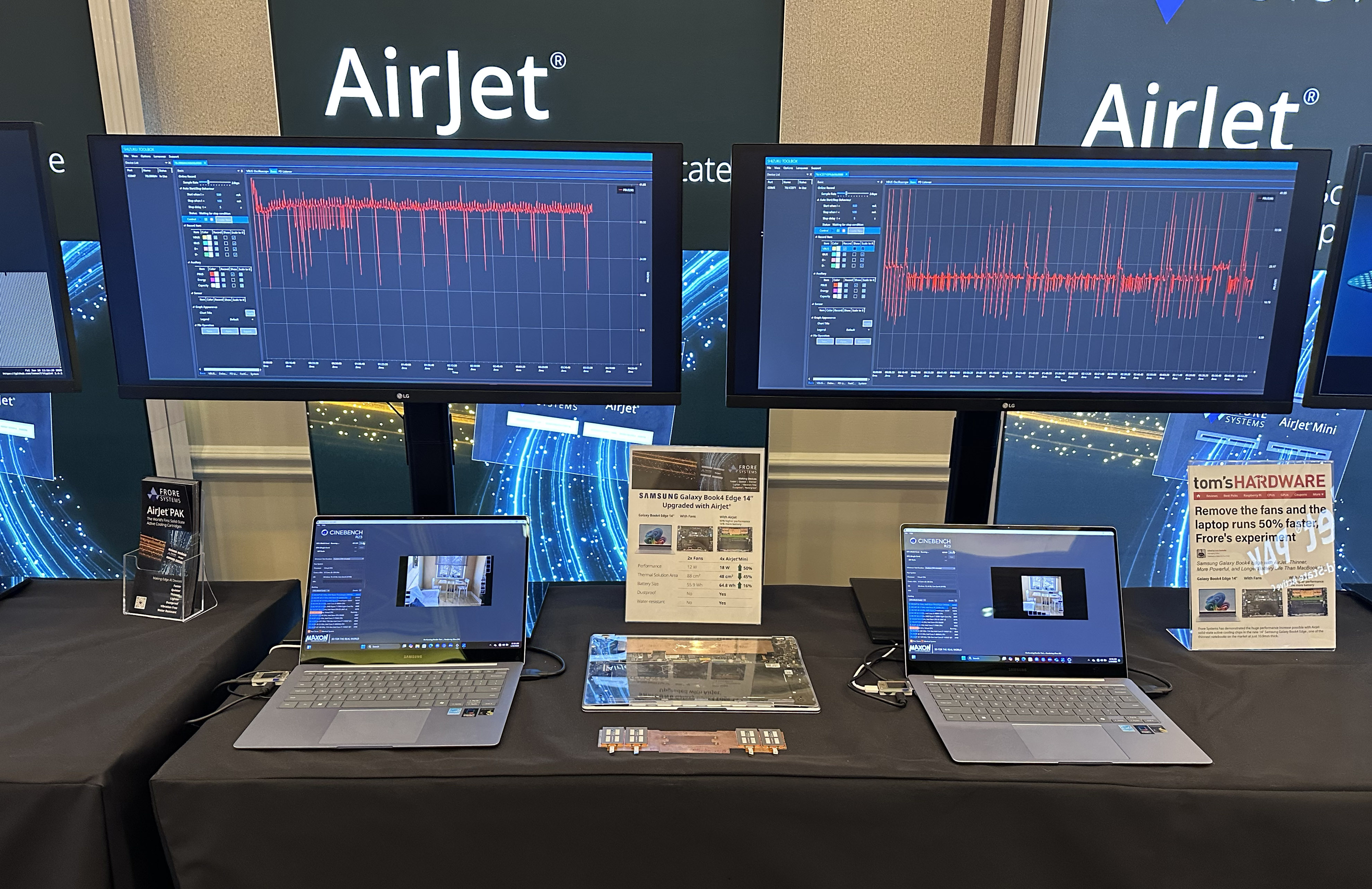

The ability to have active cooling in compact systems, where fans can’t operate, is a game changer. Like everyone, manufacturers are hungry for higher performance in smaller packages. Now, for the first time, with AirJet, that is a reality.

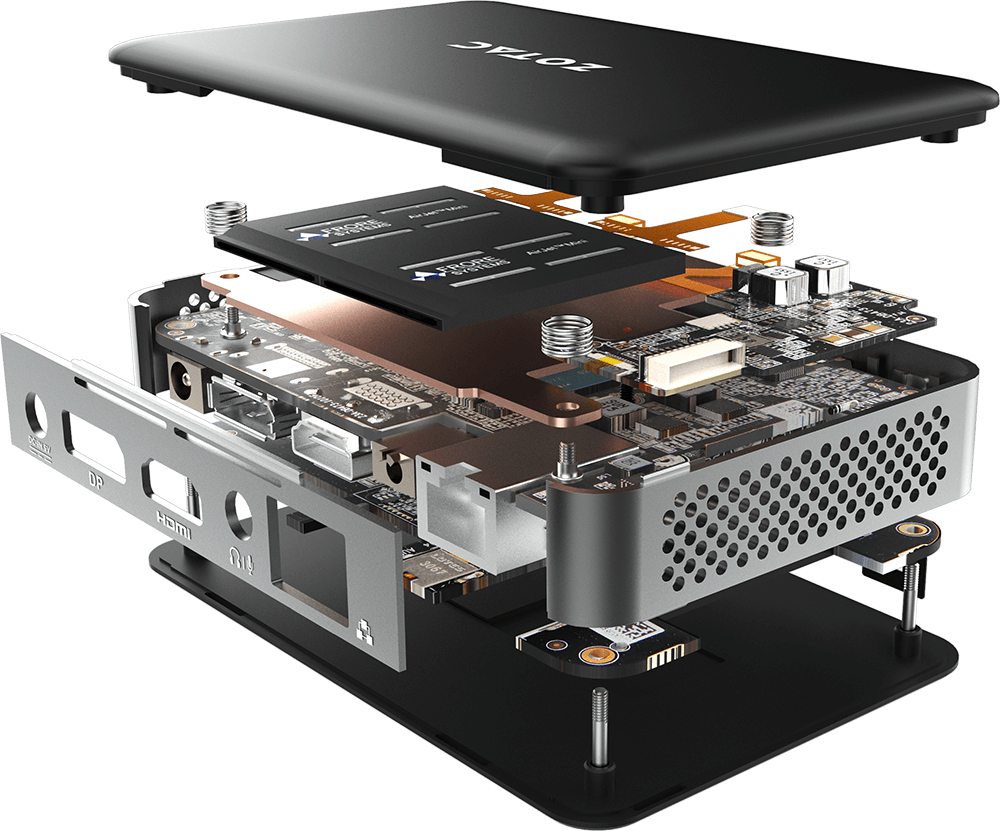

This is exactly what ZOTAC has in mind when they designed their first AirJet based actively cooled Mini PC.

The ZOTAC ZBOX PI430AJ with AirJet®, has doubled the sustained processor performance in their tiny, but powerful, 115mm x 76mm x 22 mm device delivering 7 W TDP of sustained processor performance. ZOTAC customers will now experience vastly greater functionality and higher processor performance – with a cooling system that is impervious to dust - ensuring their manufacturing lines remain high performing as well!

In addition to doubling the processor performance, the new ZOTAC Mini PC includes an impressive list of upgrades, including an Intel® Core™ i3 processor, 8 GB of LPDDR5 memory, a M.2 SSD storage slot, and more. With all this and a skin temperature reduction of almost 20%, ZOTAC has set a new standard for Mini PC performance.

As the Chief Executive Officer at ZOTAC Technology, Tony Wong, recently said, “At ZOTAC, we strongly believe that innovation is not only about improving, but rather doing something in completely new ways, which is exactly what the AirJet® offers us. The new AirJet® powered ZBOX PI430AJ delivers superior performance in a silent, miniaturized form, and we’re proud that this solid-state actively cooled mini-PC is a trailblazer in the Mini PC industry with its breakthrough cooling solution.”

Mini PC users now have an alternative to remove heat generated by ever-increasing workloads. A solution, much better than reducing performance, or relying on antiquated thermal approaches like throttling, noisy mechanical fans or bulky ineffective heat sinks.

AirJet’s, the world’s first solid-state active cooling chip, is just 2.8mm thick, 27.5mm x 41.5mm in size, and light weight, under 11 grams. Its compact size and silent, high performance, means AirJet can remove heat from devices that have previously been unable to use active cooling.

AirJet is a scalable solution, with additional heat removal – and increased performance - achievable by simply adding more AirJet chips. Each chip removes 5W of heat, and the easy integration of multiple chips means two chips can remove 10W, three chips 15W and so on. AirJet’s compact size and scalable nature means manufacturers can adopt the heat removal technology in a wide range of applications, enabling increased performance in faster, thinner, lighter, silent, and dustproof devices.