In precision inspection, clarity isn’t just expected — it’s essential. Whether you're analyzing semiconductor stacks, identifying contamination on a food line, or spotting micro-defects in solar cells, your imaging system needs to deliver flawless results. For users of SWIR (Short-Wave Infrared) cameras, that level of accuracy depends on one key factor: sensor temperature stability.

Until now, achieving that stability came at a cost.

The Thermal Trade-Off

SWIR cameras often rely on Thermoelectric Cooling (TEC) to regulate their sensors. While TECs help cool the sensor itself, they also cause the overall internal camera temperature to rise — limiting performance, reducing sensor stability, and introducing thermal noise over time.

The result? Heat buildup that directly impacts image quality, especially during continuous or high-speed inspection cycles.

Enter AirJet®: Solid-State Cooling That Stabilizes Everything

The integration of AirJet® changes the game.

By actively removing heat from the camera housing — without fans, vents, or moving parts — AirJet® keeps the entire system cool. This improves TEC efficiency and prevents thermal drift, allowing the sensor to maintain its ideal temperature for longer periods.

In test systems, AirJet® reduced sensor temperature from 45°C to just 15°C — dramatically improving thermal stability and enabling sharper, more consistent imaging throughout extended operations.

Before vs. After: What Changes for the End User

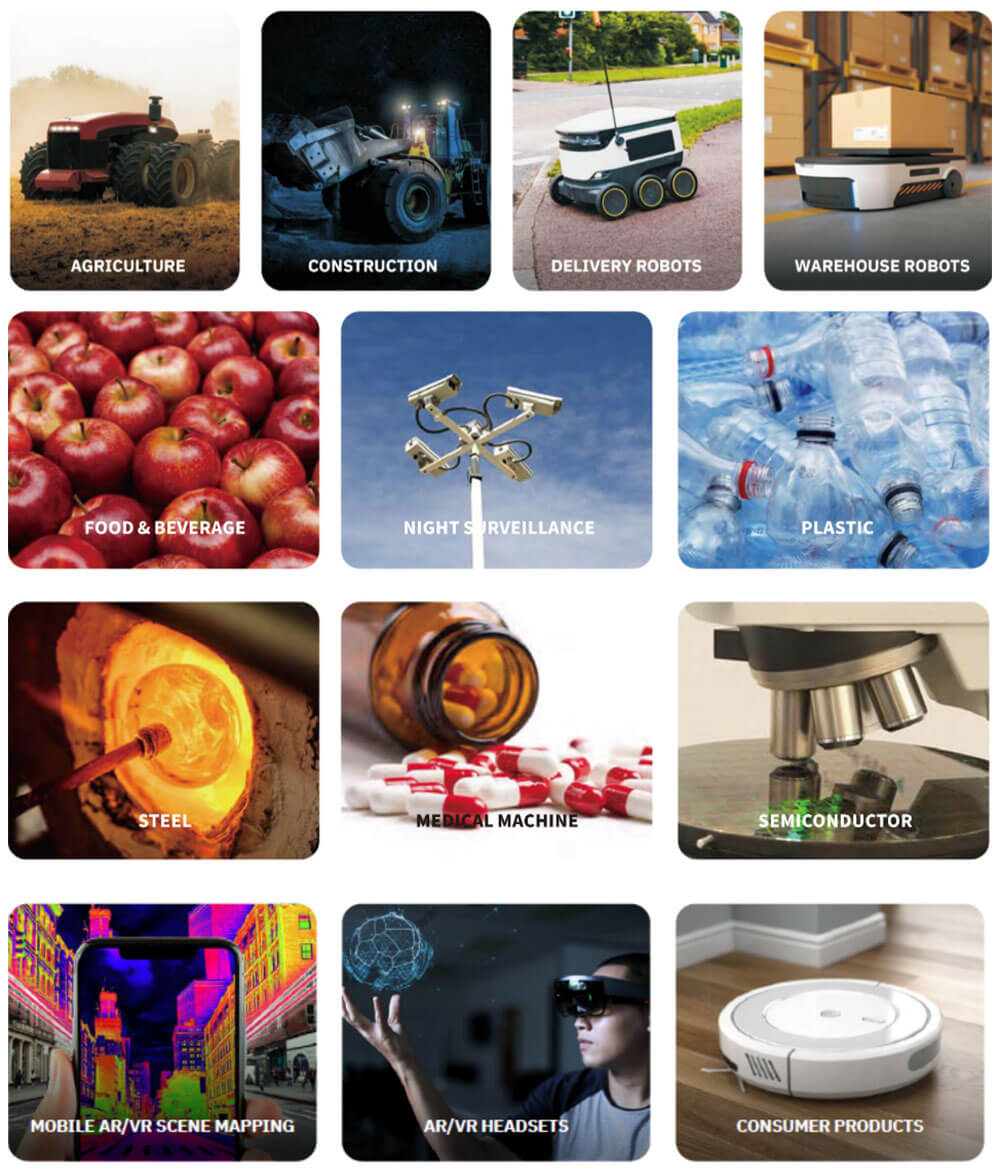

Where It Matters Most: Real-World Applications

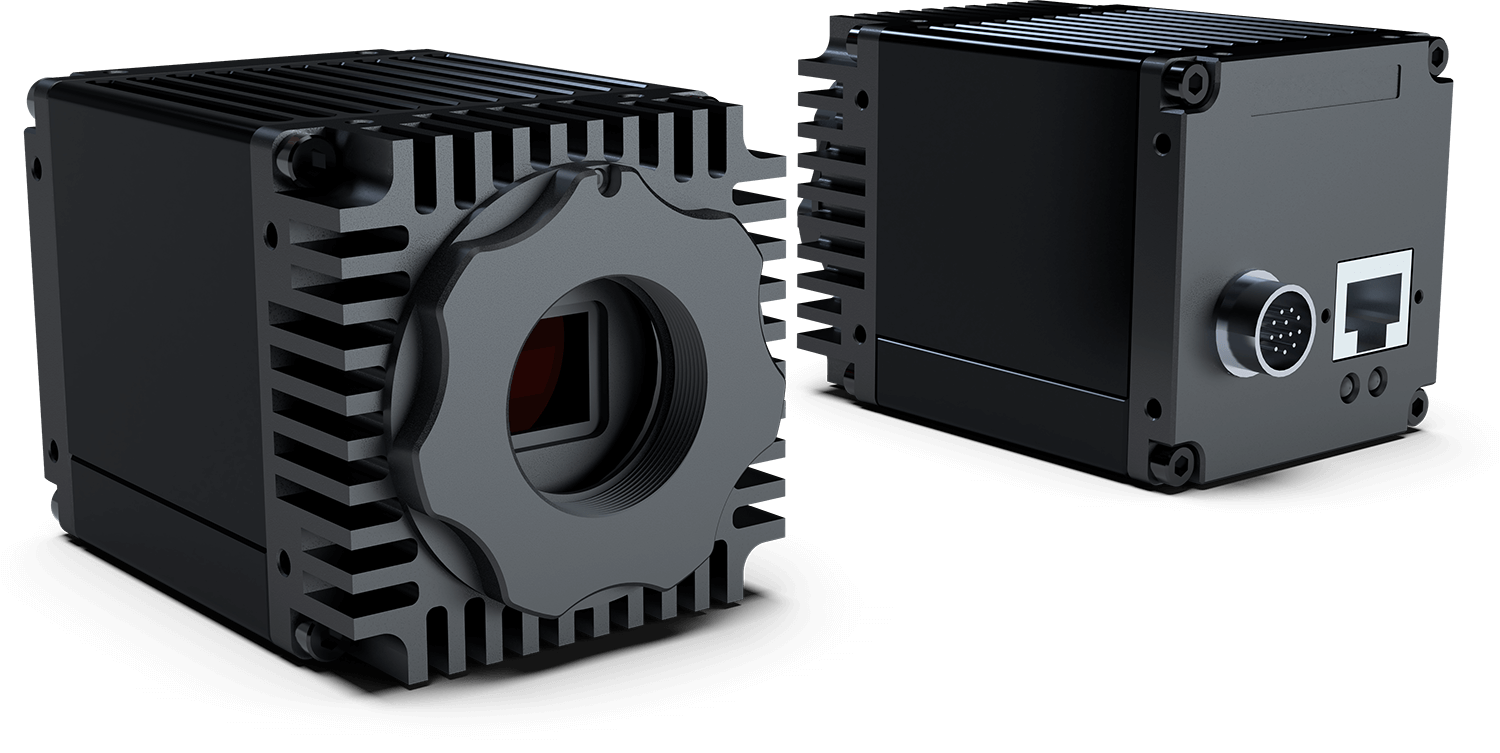

CREVIS, a leading manufacturer of machine vision cameras for global industrial applications, is an early adopter of the AirJet Mini Gen 2. “As a leader in industrial machine vision, it's essential that our products meet the latest demands of our customers,” said Mr. Jun-Heoun Hwang, CEO of CREVIS. “By integrating the AirJet Mini Gen 2 into our cameras, we’re able to achieve better image quality with lower noise, higher frame rates, and still maintain a compact and cool design. For a long time, heat issues had limited our performance — but this incredible technology helps us overcome those barriers. It’s a true game-changer and a key differentiator for us in the market.” Pictured: Crevis’ CoaXPress.

AirJet®-cooled SWIR cameras deliver faster, more accurate, and more stable performance across a wide range of industrial and mission-critical use cases:

🔬 Semiconductor & Display

- Wafer penetration inspection

- HBM stacking and alignment

🔋Secondary Battery

- Separation membrane integrity checks

- Non-destructive defect detection

🍫 Food & Beverage

- Foreign object and contaminant detection

- Pollutant analysis and real-time QA

🛡️ Surveillance

- Improved visibility in nighttime and adverse weather

🩺 Biomedical

- Vascular and tissue visualization

- Eye examinations and subdermal imaging

☀️ Solar Power

- PV defect detection

- A more precise alternative to NIR in panel inspection

🤖 Autonomous Robotics & Automotive

- Environmental sensing in low-visibility conditions

- Safe navigation for robots, AGVs, and vehicles in dynamic environments

Conclusion: When Heat Fades, Vision Sharpens

By solving a silent limiting factor — heat — AirJet® unlocks the full potential of SWIR imaging. Better temperature control means clearer images, longer runtimes, and smarter automation across sectors that rely on precision and reliability.

Whether you're inspecting the smallest defect on a semiconductor wafer or ensuring autonomous systems can see in the dark, AirJet® brings the stability you need to trust the image — and the system behind it.

Because in a world that demands flawless vision, cooling isn’t optional. It’s mission-critical.

Applications for SWIR Cameras